Balancing a centrifuge requires that all tubes in the load are properly distributed to ensure safe and effective operation. This comprehensive guide delves into the principles, procedures, and safety considerations involved in centrifuge balancing, providing a thorough understanding for laboratory professionals and researchers.

Understanding the forces at play during centrifugation and the role of counterweights in maintaining balance is crucial for achieving accurate and reliable results. Proper loading and unloading techniques, as well as troubleshooting common imbalance issues, are essential to minimize risks and maximize centrifuge performance.

Principles of Centrifuge Balancing

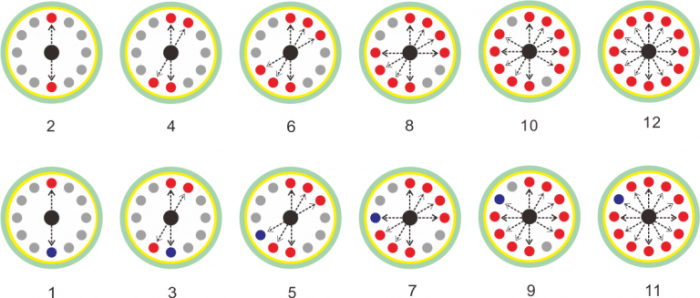

Centrifuge balancing is a critical aspect of centrifuge operation that ensures the smooth and efficient functioning of the equipment. It involves distributing the weight of the samples and counterweights evenly within the centrifuge rotor to minimize vibrations and maintain equilibrium during high-speed operation.

The forces involved in centrifuge operation include centrifugal force, which acts outward from the center of rotation, and gravitational force, which acts downward. When the centrifuge is unbalanced, these forces create vibrations that can damage the equipment, compromise the integrity of the samples, and lead to inaccurate results.

Counterweights play a crucial role in balancing by adding mass to the opposite side of the rotor from the samples. By carefully adjusting the position and weight of the counterweights, the centrifuge operator can achieve a balanced load that minimizes vibrations and ensures optimal performance.

Loading and Unloading Procedures

Proper loading and unloading procedures are essential for maintaining centrifuge balance and preventing accidents.

- Always load and unload the centrifuge at low speed.

- Ensure that the tubes are securely placed in the rotor and that they are evenly distributed.

- Avoid overloading the centrifuge or using tubes that are not designed for the specific centrifuge model.

- When loading or unloading tubes of different sizes or weights, adjust the counterweights accordingly to maintain balance.

Improper loading can lead to imbalance, which can cause the centrifuge to vibrate excessively, damage the equipment, and compromise the integrity of the samples.

Troubleshooting Imbalance Issues: Balancing A Centrifuge Requires That All Tubes In The Load

Common signs and symptoms of centrifuge imbalance include excessive vibrations, noise, and uneven sample distribution after centrifugation.

Potential causes of imbalance include:

- Uneven tube loading

- Tube damage

- Improperly placed counterweights

- Mechanical issues with the centrifuge

To troubleshoot and resolve imbalance issues, follow these steps:

- Check the tube loading and ensure that the tubes are evenly distributed.

- Inspect the tubes for any damage or leaks.

- Adjust the position or weight of the counterweights as needed.

- If the imbalance persists, contact the centrifuge manufacturer for further assistance.

Safety Considerations

Centrifuge operation involves potential safety hazards that must be addressed to ensure the safety of the operator and others in the vicinity.

Proper safety protocols include:

- Wearing appropriate protective gear, including gloves, safety glasses, and a lab coat.

- Following the manufacturer’s instructions for safe operation and maintenance.

- Handling hazardous materials according to established protocols.

- Disposing of biohazardous waste properly.

By adhering to these safety precautions, operators can minimize the risks associated with centrifuge operation and ensure a safe working environment.

Key Questions Answered

Why is it important to balance a centrifuge?

Balancing a centrifuge ensures even distribution of weight during rotation, preventing excessive vibrations and potential damage to the centrifuge or tubes.

What are the potential consequences of improper centrifuge loading?

Improper loading can lead to imbalance, causing vibrations, noise, and potential damage to the centrifuge and its components, as well as affecting the accuracy of results.

How can I identify common signs of centrifuge imbalance?

Signs of imbalance include excessive vibrations, unusual noises, and uneven acceleration or deceleration during centrifugation.